Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

Positioning Systems & Actuators

Positioning systems and actuators play pivotal roles in motion control systems, orchestrating the desired motion. The core of their functionality lies in the conversion of energy into mechanical motion, which can either be rotary or linear.

Actuators serve this purpose by transforming various types of energy, including electrical, hydraulic, and pneumatic, into physical movement. This movement can be rotational as in the case of motors, or linear as in the case of linear actuators. A linear actuator, in particular, is a device that specializes in transforming energy into linear motion, making them ideal for a variety of applications that necessitate precise straight-line movement.

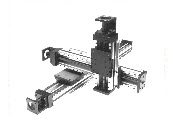

On the other hand, positioning systems typically consist of a rigid base, a ball or acme screw for motion transfer, and a servo or stepper motor coupled with a drive for motion generation. These systems are designed for ease of use and turnkey operation, providing precise control over the position of an object. They are often employed in applications such as CNC machines, robotics, and conveyor systems where precise, controlled movement is vital.

Types of Linear Actuators

There are a number of different types of linear actuators.

- Screw Actuators: screw actuators can be either lead screw actuators (those with a threaded nut that moves with a screw), ball screw actuators (a lead screw actuator that uses ball bearings), or planetary roller screw actuators (a lead screw actuator with threaded rollers around the main threaded shaft)

- Belt Actuators: actuators based on belt drives. These are typically used in applications where speed is important.

- Rod & Rodless Actuators: Rod: As motion occurs, the rod moves out of the end of the actuator. These produce more force and are tolerant of dirty environments. They require a bearing structure to carry the load. Rodless: The housing of the actuator completely surrounds the screw, providing a load bearing and guidance structure. These are difficult to seal for dirty or wet environments.

- Integrated Actuators: Integrate a rod actuator into a motor housing. This eliminates the need for a coupling. These actuators provide the lowest size and weight, with easier maintenance, but at a higher cost.

Types of Positioning Systems

- Screw Driven Positioning Stages: used in instances where accuracy and repeatability take precedence over axial thrust forces. All sub-assembly components are precision machined to contribute to the overall accuracy and repeatability of the stage. The drive mechanisms of the position tables are either acme or ball screw with linear bearings used to carry the user load.

- Belt Driven Positioning Stages: used in high speed positioning applications where using a screw driven positioning stage is impractical. Belt driven positioning stages have a unique ability to provide the same speed capability independent of travel length.

- High Accuracy Positioning Tables/Nano Precision Stages: used in applications where high accuracy and repeatability and/or smoothness are critical features. Much like screw driven positioning stages, all sub-assembly components are machined to tight tolerances for accuracy and repeatability.

For more information, browse our selection of positioning systems & actuators below!