Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

- Buy 10 for $314.00 each and save 3%

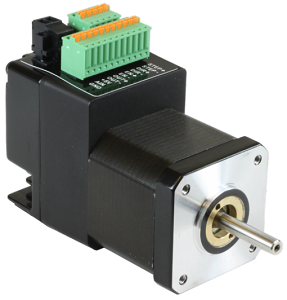

The STM23R-2NE integrated stepper is a drive+motor unit, fusing a NEMA 23 step motor and a sophisticated 5.0 A/phase (peak-of-sine) stepper drive into a single device. Power to the drive, located at the rear of the motor, must be supplied by an external DC supply. See Related and Recommended Products below for compatible 24 and 48 volt DC power supplies.

The STM23R-2NE is designed for step & direction control from an external controller. The external controller can be a motion controller, PLC, or other device that provides two digital outputs: one output for digital pulses to control position and velocity of the motor, and a second output to control the direction of the motor, CW and CCW. Some controllers provide two pulse outputs – referred to as CW/CCW pulse or pulse-pulse – instead of pulse & direction.

The STM23R works with these controllers as well simply by changing one of the setup dip switches. Note that STM23R integrated steppers are not available with any communication options (such as Ethernet, RS-485, etc.) or additional control modes (such as velocity, streaming commands or Q programming). For these and other functions see other models in the STM23 integrated stepper family .

The STM23R-2NE comes with a 1000-line, incremental encoder assembled to the rear shaft of the unit. The A, B and Index (Z) channel signals of this encoder can be connected back to the external controller for position verification and enhanced performance, depending on the features of the controller. To facilitate connecting the encoder signals to your external controller, each motor comes with a 3 ft. extension cable in the box (cable part number 3004-263). A version of the STM23R with just the rear shaft but no encoder is also available, STM23R-2ND, as well as a single-shaft version, STM23R-2NN. Each STM23R integrated stepper comes with 3 digital inputs and 1 digital output. Two of the digital inputs (labeled STEP and DIR) accept signals of 5-24 VDC and are used for controlling position and velocity of the motor, either via pulse & direction or CW/CCW pulse outputs from an external controller. The third digital input (EN) accepts signals of 5-24 VDC and can be used to enable/disable power to the motor shaft. The digital output (OUT) can be used to indicate drive and motor faults by connecting it to an available digital input on the external controller.

To facilitate connecting I/O signals and DC power to the STM23R, a mating connector with 12-inch flying leads is included with each unit.

All STM23R integrated steppers are RoHS compliant.

Features

| Manufacturer | Applied Motion Products |

|---|---|

| Feedback | Incremental Encoder |

| Max Holding Torque (mNm) | 883.00 |

| Max Holding Torque oz (in) | 125.00 |

| Max Length (mm) | 85.00 |

| Min Operating Temperature (°C) | 0.00 |

| Min Operating Temperature (°F) | 32.00 |

| Max Operating Temperature (°C) | 85.00 |

| Max Operating Temperature (°F) | 185.00 |

| Shaft Diameter (mm) | 6.35 |

| Shaft Diameter (in) | 0.25 |

| Max Input Supply Voltage (VDC) | 70.00 |

| Motor Construction | Hybrid Stepper |

| NEMA Frame Size | 23 |

| Number of Axes | 1 |

| Operating Mode | Step & Direction |

| Rotor Inertia (kg-m-s²) | 2.60E-05 |

| Rotor Inertia (oz-in-s²) | 3.68E-03 |

| Setup | Software Setup |

| Shaft Orientation | In-line,Double-ended (Encoder mounted) |

| Step Angle (°) | 1.8 |

| Product Category | Integrated Motors |

Sample image only. Product may differ